Sonic Acoustic Walls

Maximum noise control for industrial settings

Sonic Acoustic Walls

Key Applications

-

Engines and Generators

-

Large HVAC systems

-

Impact Noise

-

Control rooms

-

Personal access doors

-

Manufacturing facilities

-

Pump stations

Our Sonic Acoustic Walls are designed to deliver exceptional noise reduction performance in diverse environments. Whether it’s reducing industrial machinery noise or other sources of noise pollution, our acoustic walls effectively absorb and attenuate sound to create a quieter and more comfortable environment.

Key Benefits

-

Exceptional Noise Reduction

Designed to effectively absorb and attenuate sound, which is crucial for creating quieter environments in industrial and noise-prone areas.

-

Rigorous Testing and Compliance

NATA-tested and certified to AS 1191-2002 standards, ensuring adherence to industry regulations for safety and effectiveness.

-

Customisable Specifications

Offers tailored solutions based on specific noise reduction requirements and site conditions to meet unique project needs.

-

Flexible Solutions

The Sonic Curtain Acoustic Flexible Curtain Noise Walls allow for easy relocation and adaptability on construction and drilling sites, enhancing operational efficiency.

-

Durable Construction

It is built with high-quality materials and innovative design techniques, ensuring longevity and optimal performance even in challenging environments.

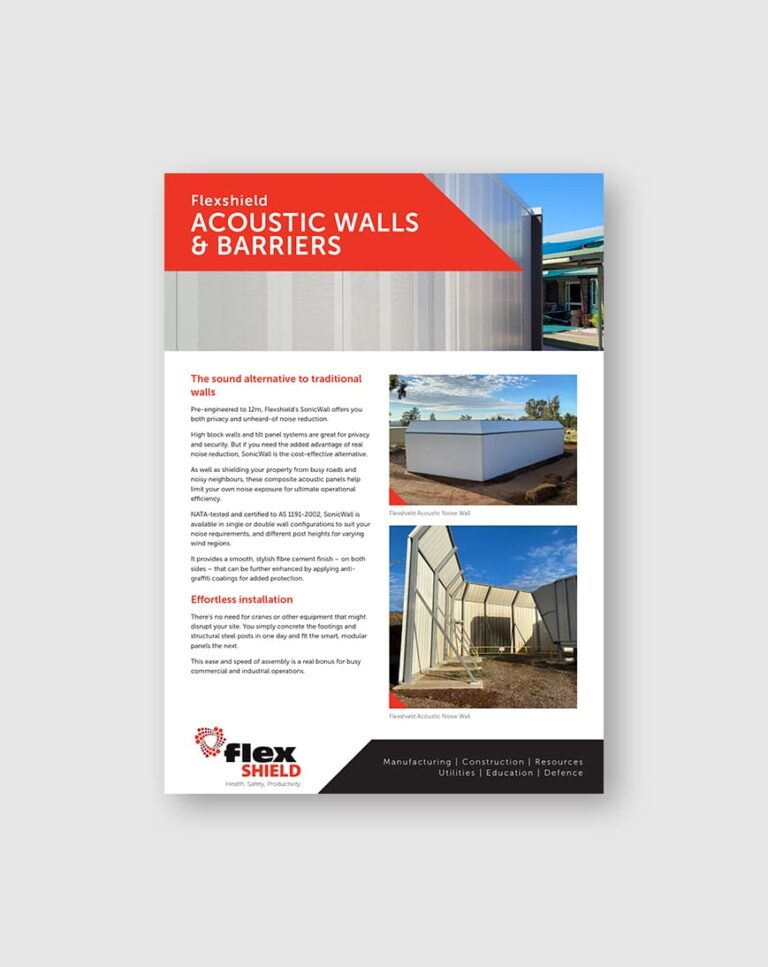

Photo & Video Gallery

-

Transform Your Site with Sonic Acoustic Walls – The Ultimate Noise Control Solution

Reduce industrial noise effectively with Sonic Acoustic Walls, designed to absorb and attenuate noise without altering the source. Trusted by Australia’s largest infrastructure, resources, and utilities projects, these walls ensure compliance, durability, and superior performance.

- Proven noise reduction for pumps, tunnels, and industrial sites

- Modular design with access points and vision panels

- Certified to AS 1191-2002 for industry compliance

Download the brochure now or contact us for a consultation to find the perfect noise control solution for your project.

-

Sonic Acoustic Wall Construction

- AcousTech’s Sonic Acoustic Walls are built using high-quality materials and innovative design techniques to ensure durability, longevity, and optimal performance. Our Sonic System Acoustic Modular Panels feature a metal skin acoustic sandwich panel construction, allowing for seamless integration of access points.

- Soundproof acoustic walls can be constructed from various materials depending on the application and sound control requirements. Acoustic walls are designed to absorb or attenuate noise and contain it within the surrounding noise source. They can also incorporate vision panels and access points as needed.

- Sonic Curtain Acoustic Flexible Curtain Noise Walls are a great choice when flexibility, constant wall shifts, or relocation is required. They are also an excellent option for mobile noise barriers on construction sites, drilling sites, and earthworks.

-

Sonic Acoustic Wall Testing and Compliance

Our panels undergo rigorous testing and certification to ensure industry standards and regulations compliance. NATA-tested and certified to AS 1191-2002 standards, our Sonic Acoustic Walls meet the highest quality and performance criteria, providing our clients and stakeholders with a sense of reassurance and peace of mind.

-

How to Specify Sonic Acoustic Walls

When specifying Sonic Acoustic Walls for your project, please consider the noise reduction requirements, site conditions, wind regions, and project specifications. Our dedicated team of experts at AcousTech is committed to providing tailored solutions and guidance, ensuring you select the right system for your needs. We value your project and are here to support you every step of the way.

Where allocated, please supply AcousTech Sonic Acoustic Walls.

The wall shall have the following features:

- Industrial Wall to have an acoustic rating of Rw_______ and Sound Transmission Loss per frequency band as below:

- Sound Transmission Loss (TL) (dB) 125, 250, 500, 1K, 2K, 4K

- Fabricated and installed to manufacturer specifications.

- Quantity and sizes found on drawing numbers: _________

Phone: 1300 508 232

Email: enquiry@acoustech.com.au

- Industrial Wall to have an acoustic rating of Rw_______ and Sound Transmission Loss per frequency band as below: