The advantage of specifying high-performance acoustic materials

Unpacking the long-term benefits of choosing more robust solutions Noise is a known variable in industrial environments. What matters is how it’s managed. In high-output facilities, the acoustic load can influence everything from operational flow and communication to worker fatigue and compliance outcomes. Managing it requires more than basic treatment. It calls for systems built…

Unpacking the long-term benefits of choosing more robust solutions

Noise is a known variable in industrial environments. What matters is how it’s managed.

In high-output facilities, the acoustic load can influence everything from operational flow and communication to worker fatigue and compliance outcomes. Managing it requires more than basic treatment. It calls for systems built to address complex sound paths with precision, and materials that maintain their acoustic integrity under real-world conditions.

Acoustic performance is measurable, and material choice matters

Noise control is not a one-size-fits-all task. It involves absorption, isolation, reflection control, and transmission loss. Each outcome relies on the right material properties, such as density, surface geometry, flow resistivity, and modularity.

Low-grade materials tend to underperform on key acoustic benchmarks:

- Low mass results in poor transmission loss (Rw values)

- Minimal absorption causes high reverberation times (RT60)

- Poor durability means materials degrade when exposed to moisture, vibration, or particulate matter

In contrast, high-performance acoustic materials are engineered to meet defined acoustic and mechanical specifications. Their results are predictable, reliable, and repeatable across applications.

The benefits of using engineered industrial noise control systems

Projects that specify fit-for-purpose acoustic systems gain several practical and operational advantages:

1) Reduced rework and faster commissioning

Correctly matched acoustic systems resolve the issue upfront. That means less on-site adjustment, fewer delays, and consistent acoustic outcomes without overengineering.

2) Verified acoustic performance

All AcousTech acoustic solutions are backed by independent test data, including Rw ratings, STL curves, and absorption coefficients, so design teams can model acoustic impact before installation.

3) Long service life

High-quality panels, louvres, and doors maintain their performance across exposure cycles, critical in environments with temperature fluctuation, chemical exposure, or continuous vibration.

4) Flexible installation and integration

Modular systems, like acoustic panels and curtain barriers, allow for staged installation, expansion, or relocation without performance loss.

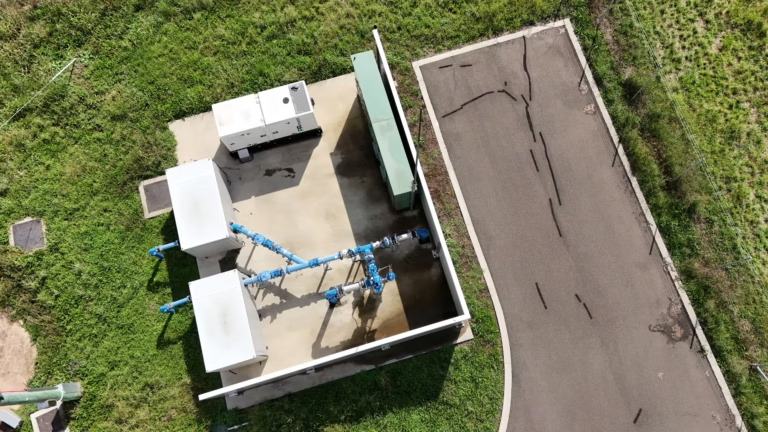

Acoustic solutions designed for industrial environments

AcousTech designs and supplies advanced acoustic systems, developed by the Flexshield Group, that address airborne noise in manufacturing, energy, water, defence, and infrastructure projects. These include:

Tested to achieve Rw ratings up to Rw46, these door systems feature high-density cores, full perimeter seals, and optional fire-rated skins. Suitable for mechanical plant rooms, switchboards, and generator housings.

Combining aerodynamic airflow with noise attenuation, these louvres provide insertion loss up to 30 dB depending on configuration. Designed for substations, chemical plants, and industrial HVAC systems.

Prefabricated panels with modular framing and composite construction, offering high STC values with rapid installation. Common applications include equipment enclosures, internal partitions, and perimeter barriers.

Flexible barrier-absorption panels with weighted cores, designed for high-noise areas that require spatial adaptability. These systems are ideal for temporary worksites, mobile plant areas, and retrofit scenarios.

The value of long-term acoustic performance

While upfront pricing is a common pressure point, the long-term benefits of using technically robust systems far outweigh the marginal savings of entry-level alternatives.

Correctly specified noise control reduces long-term maintenance, supports compliance with workplace and environmental regulations, and maintains its acoustic properties long after installation.

For specification support, acoustic data sheets, or system advice tailored to your site conditions, call AcousTech on 1300 508 232.

Trusted by engineers, built for performance. Powered by Flexshield.

That’s the Science of Silence.

Related Stories

-

Reshaping industrial noise control with sound science

How the AcousTech approach is revolutionising sound in Australia A quiet shift is happening across Australia’s industrial landscape. From high-output processing plants to remote infrastructure hubs, sound is no longer being treated as background clutter…. -

Smart industrial soundproofing solutions to transform your worksite

Noise control is not a nice-to-have – it’s a necessity Whether your industrial site is a mine, processing facility, or infrastructure project, its sound has a way of pushing its way into places it does… -

Why acoustics matter to us – and to your project

We don’t just install acoustic panels; we design silence with intent At AcousTech, sound isn’t an afterthought. It’s the thread running through every system we create, every project we contribute to, and every problem we…