Sonic Acoustic Attenuator

Engineered Ventilation Noise Control Without Compromising Airflow

-

Backed by the Science of Silence

Powered by Flexshield

Manufactured by Flexshield, AcousTech Sonic acoustic attenuators are built in Australia using high-performance materials and controlled processes to ensure consistent acoustic and airflow outcomes.Trusted by engineers and built for performance

Engineers specify Sonic acoustic attenuators for their reliable noise reduction, pressure drop control, and integration into mechanical and ventilation systems across industrial and infrastructure projects.

Key Applications

- HVAC and mechanical services

- Power generation ventilation

- Generator exhaust and intake systems

- Data centre cooling infrastructure

- Gas turbine enclosures

- Pump station and plant room ventilation

- Industrial and mining duct systems

- Marine and offshore installations

Performance

- Noise Reduction: 10–50 dB(A)

- Pressure Loss: Optimised based on system conditions

- Airflow Efficiency: Designed to suit duct velocity and volume

- Temperature Range: High-temperature options available

- Custom Pressure Ratings: Including high static systems

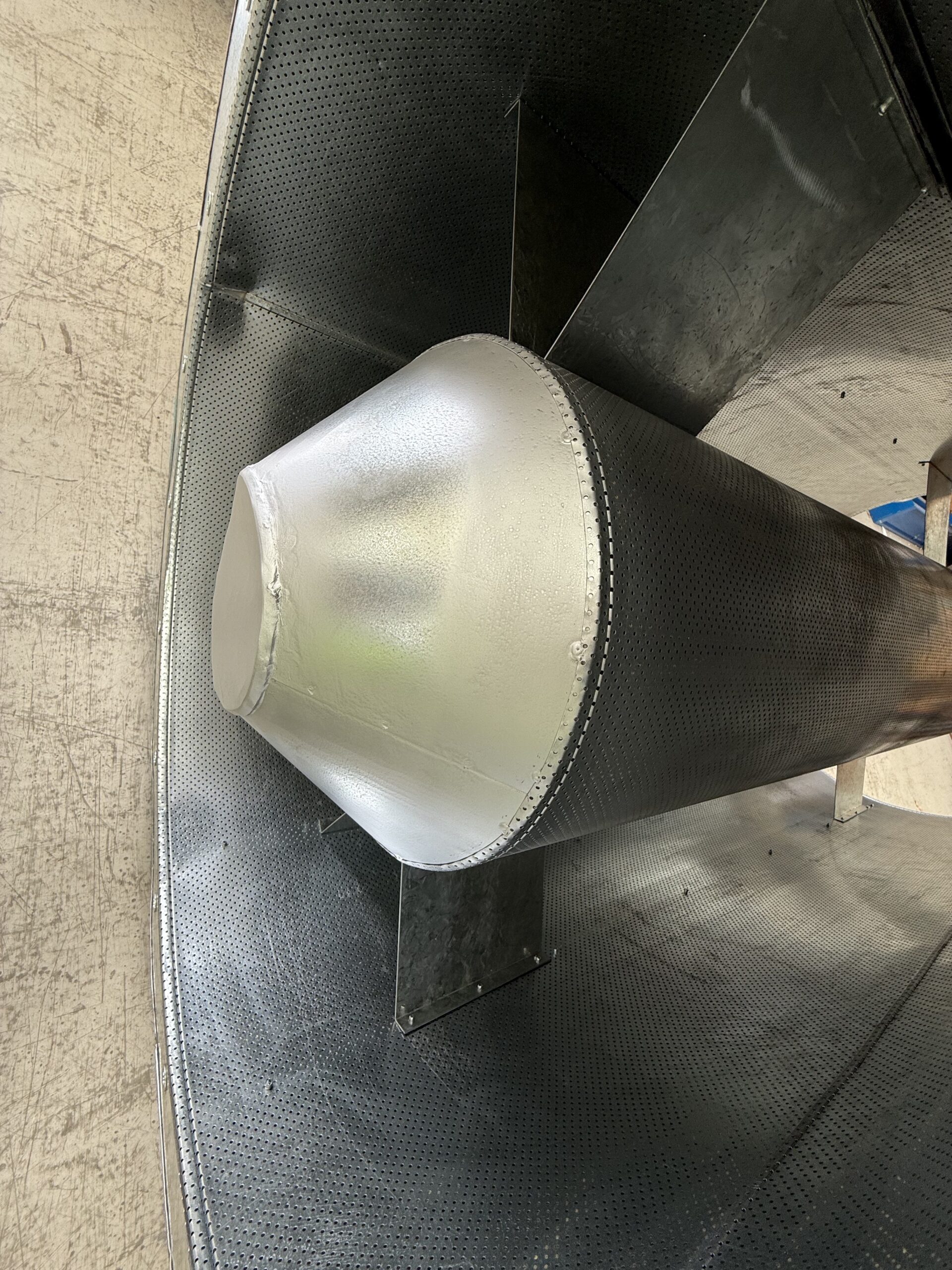

Construction

Designed to Integrate, Built to Last

All Sonic Acoustic Attenuators are manufactured to meet structural and acoustic requirements while ensuring ease of installation and long service life.

Standard Construction

- Galvanised steel casing and baffles

- Perforated internal linings

- High-density acoustic infill

- Aerodynamic pod design for noise dissipation

- Weather-resistant finish

Material Options

- Stainless steel

- Aluminium

- Corrosion-resistant coatings

- High-temperature linings and insulation

Optional Features

-

- Bird or vermin mesh

- Weather hoods or screens

- Mounting flanges or support frames

- Flexible connectors

- Access panels for inspection and cleaning

Testing & Compliance

Testing and Certification

-

- Acoustic Testing: ISO 7235:2023

- Pressure Drop Testing: Verified in airflow rigs

- Structural Integrity: Engineering sign-off available

- NATA Certification: Available for all test data

- Fire Rating: To project specification

- Environmental Compliance: Built for indoor and outdoor exposure

How To Specify

Our team works with consultants, engineers and contractors to configure attenuators that meet acoustic, airflow and spatial constraints.

- Define Your System Requirements

- Airflow volume and velocity

- Static pressure ratings

- Noise reduction targets

- Available space and layout

- Ambient and system temperatures

- Select Design Parameters

- Configuration: Rectangular or circular

- Podded or unpodded baffle layout

- Material selection for casing and internals

- Connection method: Flanged, spigot or custom

- Weather or screening protection

- Technical and Installation Details

- Support structures or hanging requirements

- Maintenance access or inspection ports

- Corrosion risk and exposure classification

- Integration with ventilation and mechanical systems

Our Process

- Initial consultation

- Performance requirements review

- Technical design and acoustic modelling

- Engineering documentation and drawings

- Local fabrication and quality control

- Installation coordination or guidance

- Performance validation on-site

Ready to Start?

Sonic Acoustic Attenuators are engineered to solve noise challenges in complex ventilation systems. Whether you’re planning a new installation or retrofitting existing infrastructure, our team can deliver a tailored solution.

-

- Request airflow and performance data

- Access specification drawings

- Obtain a project quote

- Schedule a consultation

- Review installation support options