-

Backed by the Science of Silence

Powered by Flexshield

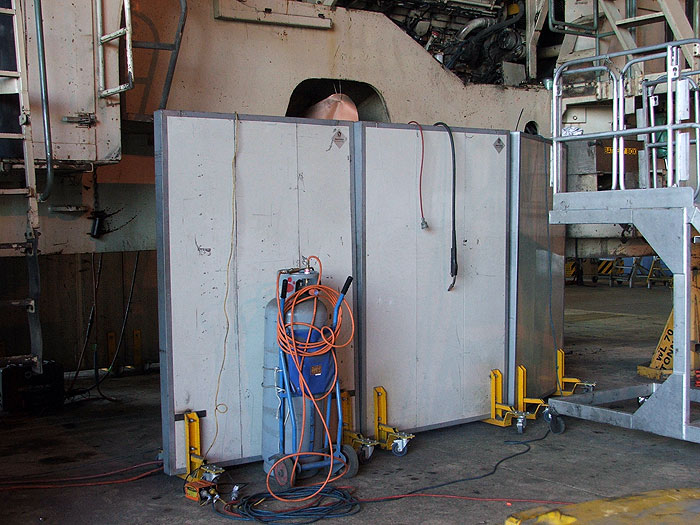

Manufactured by Flexshield, AcousTech Sonic Acoustic Mobiles are made in Australia with durable materials and rugged construction for reliable performance in demanding environments.Trusted by engineers and built for performance

Engineers specify Sonic Acoustic Mobiles for their portability, acoustic efficiency, and fast dispatch in flexible or temporary noise control applications.

Key Applications

- Maintenance and shutdown zones

- Fabrication bays and welding cells

- Grinding and air-arc gouging areas

- Machine shops and testing stations

- Assembly lines and inspection areas

- Temporary plant reconfigurations

- Training and safety separation barriers

Performance

Acoustic and Physical Performance

- Sound Absorption: NRC up to 1.10

- Sound Insulation: Up to Rw 37 dB

- Panel Sizes:

- Heights: 2100 mm to 3600 mm

- Widths: 1200 mm to 2400 mm

- Mobility: 360° swivel castors with brake locks

- Load Capacity: Industrial-grade castors rated for frequent movement

Construction

Engineered to Move. Built to Last.

Sonic Mobiles combine structural durability with acoustic integrity. Each unit is engineered to stand up to tough industrial use while offering effortless repositioning.

Standard Inclusions

- Sonic System acoustic panel (V50 or V100)

- High-density mineral wool core

- Perforated internal face and solid external face

- Heavy-duty powder-coated steel frame

- Reinforced base structure

- Lockable swivel castors for stability

Optional Features

-

- Vision or access panels

- Custom colours or finishes

- Unit linking mechanisms

- Surface treatments for indoor or outdoor use

- Additional bracing for exposed environments

Testing & Compliance

- Sound Absorption: ASTM C423-90A

- Sound Insulation: AS/NZS ISO 717.1-2004

- Fire Rating: FRL -/120/- (to AS 1530.4-2014)

- Tested and validated: NATA-accredited acoustic lab

- OH&S: Designed to support safe work environments

How To Specify

Our team works with you to deliver the right configuration for your workspace, acoustic requirements, and mobility needs.

- Define Application Requirements

- Noise source type and intensity

- Floor layout and available space

- Equipment proximity or access areas

- Internal or external use

- Configure Your Solution

- Panel thickness: V50 or V100

- Panel size: Height and width

- Frame and castor selection

- Colour and surface finish

- Unit linking or standalone

- Consider Environmental and Operational Factors

- Floor surface and mobility needs

- Weather exposure (for external use)

- Vision/access requirements

- Branding or customisation

- Storage and repositioning methods

Standard Configurations

- Heights: 2100 mm, 2400 mm, 3000 mm, 3600 mm

- Widths: 1200 mm, 1800 mm, 2400 mm

- Custom sizes available on request

Need Support?

Whether you’re setting up a temporary maintenance area or improving safety around high-noise processes, Sonic Acoustic Mobiles offer a fast, reliable solution. Let our team help configure the right units for your environment.

-

- Request a product demo

- Access CAD drawings or specs

- Get a tailored quote

- Book a site visit

- Review deployment and storage options