What is the best industrial noise control?

A look at the hierarchy of control for workplace noise Noise-Induced Hearing Loss (NIHL) is a serious risk for workers in the industrial sector. Yet the early warning signs of NIHL are subtle which is why both employers and workers have a responsibility to prevent hearing loss and future disability. The hierarchy of control system…

A look at the hierarchy of control for workplace noise

Noise-Induced Hearing Loss (NIHL) is a serious risk for workers in the industrial sector. Yet the early warning signs of NIHL are subtle which is why both employers and workers have a responsibility to prevent hearing loss and future disability.

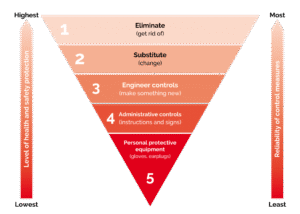

The hierarchy of control system is a step-by-step approach to eliminating or reducing risks in the workplace. It ranks risk controls, from the highest level of protection and reliability to the lowest and least reliable protection.

These levels of control for noise are:

1) Eliminating the hazard and risk by reducing noise at the source.

2) Reducing the risk through substitution, isolation and engineering controls.

3) Reducing the risk through wearing personal protective equipment (PPE).

The hierarchy of control shows that PPE should be the very last option when preventing NIHL. Instead, using engineered controls, such as Sonic System acoustic enclosures or Sonic Acoustic curtain enclosures, is the best and most effective solution to reduce the impacts of NIHL.

Reducing NIHL with engineered noise controls

Silencing machines with a noise absorbent product will reduce the risk of hearing loss better than any Personal Protective Equipment (PPE) available on the market. In fact, with the right engineered controls, employees may not need to wear PPE to avoid NIHL. Instead, noise at the source – at the machinery – is reduced to an acceptable level using an industrial noise control solution.

Flexshield industrial noise control solutions are engineered to eliminate noise at the source. Because each workplace and piece of machinery is different, each solution we recommend will be different. Industrial noise control solutions we may suggest for you include:

Acoustic Enclosures

Ideal for controlling noise from a specific source, each acoustic enclosure uses a different combination of Flexshield industrial noise control and screening solutions.

Ideal for controlling noise from a specific source, each acoustic enclosure uses a different combination of Flexshield industrial noise control and screening solutions.

While each acoustic enclosure design is unique for each application, they all feature NATA accreditation. The design considers your requirements for access, operation and maintenance, ventilation, ease of installation, and improved efficiency. Therefore we will often use a combination of our products to create the perfect enclosure.

Depending on your project needs, an acoustic enclosure may utilise our Sonic System acoustic modular panel, Sonic Series acoustic louvres, Sonic Access acoustic doors, or Sonic Acoustic Curtains.

Sonic Acoustic Curtains

Sonic Acoustic Curtains are soundproof curtains and screens that provide maximum noise reduction. They achieve superb levels of soundproofing by combining sound barrier and noise absorption products into one flexible, soundproof acoustic curtain panel.

Sonic Acoustic Curtains are soundproof curtains and screens that provide maximum noise reduction. They achieve superb levels of soundproofing by combining sound barrier and noise absorption products into one flexible, soundproof acoustic curtain panel.

The sound barrier and noise absorption technology helps operators of noise equipment adhere to the government’s regulated decibel time exposure allowance (85dBA/8hr). In addition, they can help to reduce and control the spread of dust and fumes.

Sonic Series Acoustic Louvres

Flexshield Sonic Series acoustic louvres keep noise levels down without sacrificing ventilation. In some instances, noise control can hinder the performance of the machine you are trying to silence. For example, if the ventilation around noisy machines is compromised, it can cause overheating which can affect the device’s effectiveness and reduce its lifespan.

Flexshield Sonic Series acoustic louvres keep noise levels down without sacrificing ventilation. In some instances, noise control can hinder the performance of the machine you are trying to silence. For example, if the ventilation around noisy machines is compromised, it can cause overheating which can affect the device’s effectiveness and reduce its lifespan.

Sonic Series acoustic louvres are designed to allow ventilation and all-weather protection while reducing noise levels.

All products are designed to withstand the demands of Australia’s extreme climate; therefore, they are usable inside and outside.

Contact Flexshield for more information about industrial soundproofing

Flexshield is Australia’s leading supplier of industrial noise control. Our solutions provide better protection for workers and employers by reducing the noise at the source.

As our Sales Team Leader Nathan Archer notes, “More than one of our clients has told us they’ve had to open the enclosure door to check whether the machinery is still working. That is how effective an at-source noise control solution can be.”

The Flexshield team are skilful in designing customised industrial noise control. For more information about any of our products, call 1300 799 969 or contact us online.

Related Stories

-

Flexshield’s big month in industrial noise control – on the road from QLD to WA!

Taking action for hearing health and sustainable water management It’s been a busy month for the Flexshield team, and we’ve covered vast distances from Queensland to New South Wales, Victoria, and Western Australia. It’s been… -

The science behind tailored industrial noise control solutions for your project

7 key considerations for addressing noise pollution for your project When you’re managing noise on a job site, it’s important to understand the science behind industrial noise control and how to apply it effectively. Whether… -

World Hearing Day 2025: protecting workers’ hearing with Flexshield

Why prioritising hearing protection is essential for your workforce Each year on March 3rd, the World Health Organisation (WHO) marks World Hearing Day, raising awareness about hearing loss and promoting actions to protect auditory health….