-

Backed by the Science of Silence

Flexshield Group

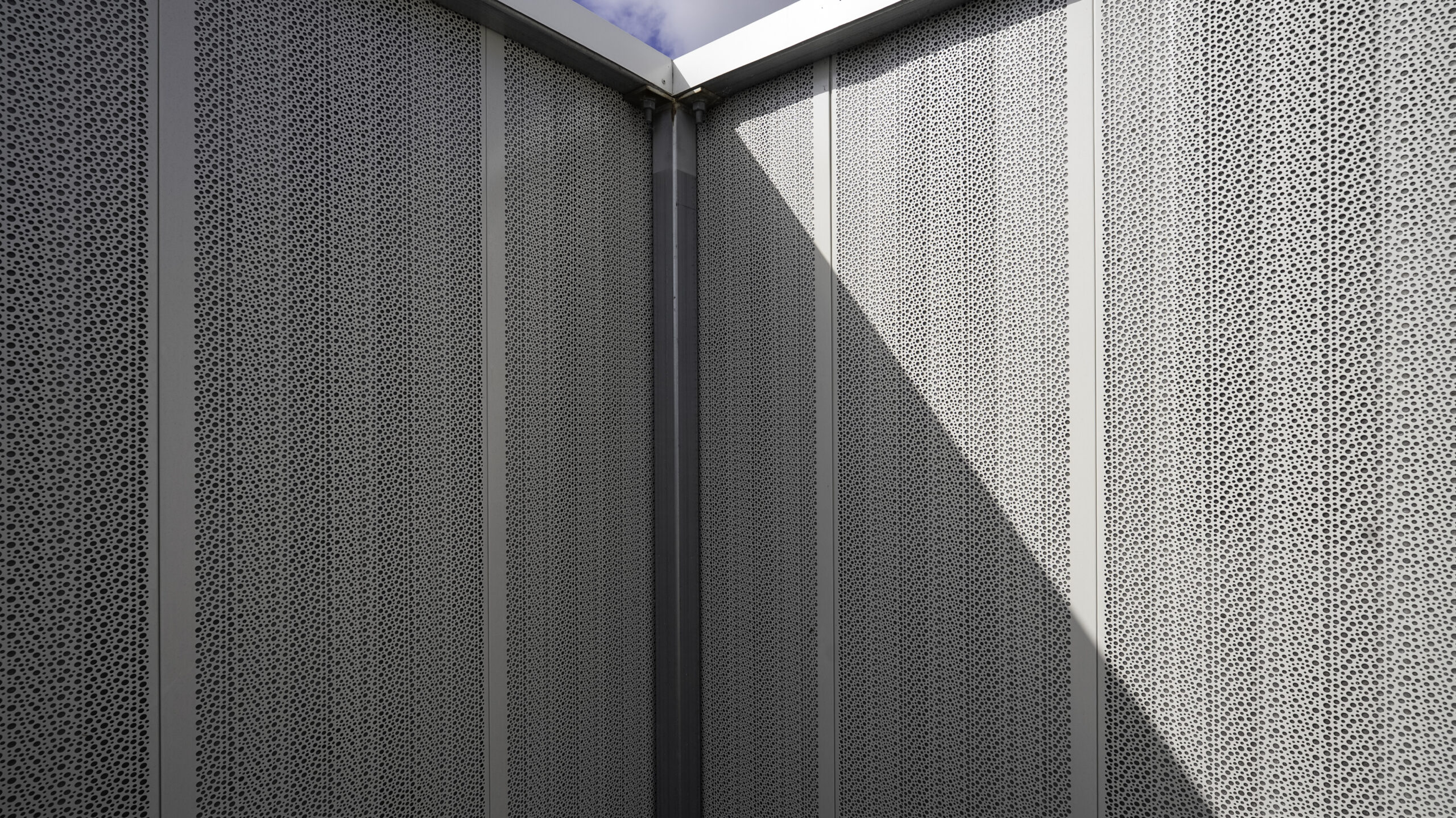

Manufactured by Flexshield, AcousTech Sonic System acoustic modular panels are made in Australia using proven designs, tested materials, and consistent manufacturing processes.Trusted by engineers and built for performance

Engineers choose Sonic System acoustic modular panels for their modular flexibility, reliable acoustic ratings, and performance on complex industrial and infrastructure projects.

-

Acoustic control engineered to specification

Rw ratings up to 47 dB | NRC values to 1.0 | Scalable modular system

Sonic System acoustic modular panels are engineered for projects where precise acoustic performance is non-negotiable. Designed for industrial and infrastructure environments, the system combines high transmission loss with superior absorption, delivering proven results in line with project acoustic criteria.

- Transmission loss: Laboratory tested to achieve up to Rw 47 dB.

- Absorption performance: NRC values up to 1.0 depending on configuration.

- Construction: High-density volcanic Rockwool core with perforated steel facing for durability and performance stability.

- Panel options: Available in 50 mm and 100 mm thicknesses to meet both acoustic and structural requirements.

- Compliance: Designed to assist with ISO 10140 and AS/NZS 1276 acoustic testing standards.

- Integration: Modular panel format allows scalable installation for test cells, plant enclosures, transformer barriers, and other industrial applications.

With predictable acoustic values, structural robustness, and installation flexibility, Sonic System acoustic modular panels provide a reliable platform for engineers and architects seeking guaranteed performance outcomes.

Key Applications

-

Industrial acoustic walls and partitions

-

Acoustic enclosures for machinery and equipment

-

External acoustic noise walls

-

Wall linings for manufacturing facilities

-

Sound control in infrastructure projects

-

Temporary and permanent noise mitigation solutions

Performance

| Panel Type | Thickness | NRC Rating | Rw (dB) | Weight (kg/m²) |

|---|---|---|---|---|

| V50 | 50mm | 1.00 | 31 | 15.6 – 17.0 |

| V100 | 100mm | 1.10 | 37 | 20.9 – 28.0 |

| V100SP | 100mm | 1.00 | 47 | 46 |

| V225 | 50mm | 0.80 | 24 | 20.1 |

Construction

SONIC SYSTEM ACOUSTIC MODULAR PANEL V50

| Category | Specification |

|---|---|

| Panel Construction | Internal steel sheet: 0.50mm External steel sheet: 0.70mm Rockwool core Perforated internal face (38% open area) |

| Standard Sizes | Width: 450mm standard Overlap connection: 25mm Thickness: 50mm |

| Custom Options | Custom sizes and colours available |

| Weight | 15.6 kg/m² |

| Surface Finish | Anti-corrosive treatment with epoxy primer Painted finish Available in pre-finished off-white |

| Thermal Transmittance | 0.70 W/m²K |

| Installation | Interlocking modular panel system, screwless assembly |

SONIC SYSTEM ACOUSTIC MODULAR PANEL V100

| Category | Specification |

|---|---|

| Panel Construction | Internal steel sheet: 0.50mm External steel sheet: 0.70mm Rockwool core Perforated internal face (38% open area) |

| Standard Sizes | Width: 450mm standard Overlap connection: 25mm Thickness: 100mm |

| Custom Options | Custom sizes and colours available |

| Weight | 28 kg/m² |

| Surface Finish | Anti-corrosive treatment with epoxy primer Painted finish Available in pre-finished off-white |

| Thermal Transmittance | 0.35 W/m²K |

| Installation | Interlocking modular panel system, screwless assembly |

SONIC SYSTEM ACOUSTIC MODULAR PANEL V100SP

| Category | Specification |

|---|---|

| Panel Construction | Internal steel sheet: 0.50mm perforated External steel sheet: 1.00mm perforated Rockwool core Structural reinforcement: 1.00mm supported steel sheet |

| Standard Sizes | Width: 450mm standard Overlap connection: 25mm Thickness: 100mm |

| Custom Options | Custom sizes and colours available |

| Weight | 46.0 kg/m² |

| Surface Finish | Anti-corrosive treatment with epoxy primer Painted finish Available in pre-finished off-white |

| Thermal Transmittance | 0.38 W/m²K |

| Installation | Interlocking modular panel system, screwless assembly |

SONIC SYSTEM ACOUSTIC MODULAR PANEL V225

| Category | Specification |

|---|---|

| Panel Construction | Internal steel sheet: 0.50mm (perforated) External steel sheet: 0.50mm (solid) Rockwool core: 50mm Perforated internal face (38% open area) |

| Standard Sizes | Width: 450mm standard Overlap connection: 25mm Thickness: 50mm |

| Custom Options | Custom sizes and colours available Tailored dimensions to eliminate on-site cutting |

| Weight | 20.1 kg/m² |

| Surface Finish | Anti-corrosive treatment with epoxy primer Painted finish Available in pre-finished off-white |

| Thermal Transmittance | 0.77 W/m²K |

| Installation | Interlocking modular panel system, screwless assembly |

SONIC SYSTEM ACOUSTIC MODULAR PANEL VR

| Category | Specification |

|---|---|

| Panel Construction | External steel sheet:0.6mm (solid) Internal steel sheet:0.5mm (micro-locked perforated – 15% FOA) Rockwool core:50–200mm Perforation:3mm diameter holes at 5mm spacing |

| Standard Sizes | Width:1000mm standard Length: up to 11,900mm Thickness:50–200mm Effective support width:120mm |

| Custom Options | Custom lengths up to 11,900mm Custom colours available Tailored dimensions to eliminate on-site cutting Integration with roof accessories |

| Weight | 14.2 kg/m² (50mm) 15.2 kg/m² (60mm) 17.2 kg/m² (80mm) 19.2 kg/m² (100mm) 21.2 kg/m² (120mm) 24.2 kg/m² (150mm) 29.2 kg/m² (200mm) |

| Surface Finish | Anti-corrosive treatment with epoxy primer Painted finish Available in pre-finished off-white Custom colours on request |

| Thermal Transmittance | 0.77 W/m²K (50mm) to 0.20 W/m²K (200mm) Tested to UNI EN 14509 and EN ISO 6946 |

| Installation | Self-supporting roof panel system Interlocking joint detail Wide-span design for rapid installation Effective support width: 120mm |

Testing & Compliance

| Product | Compliance & Testing |

|---|---|

| V50 | Sound absorption tested in accordance with AS ISO 354 Tested in accordance with AS 1191-2002, with Rw determined to AS/NZS ISO 717.1 Load tested and engineering-assessed in accordance with AS 1170.2 Fire safety tested to AS 1530.4-2014 (Sections 1, 2 & 3) All testing conducted by NATA-accredited laboratories Full test certificates available upon request |

| V100 | Sound absorption tested in accordance with AS ISO 354 Sound insulation tested to AS/NZS ISO 717.1:2004 Tested in accordance with AS 1191-2002, with Rw determined to AS/NZS ISO 717.1 Fire resistance tested in accordance with AS 1530.4-2014, achieving FRL –/120/– All testing conducted by NATA-accredited laboratories Full test certificates available upon request |

| V100SP | Sound absorption tested in accordance with AS ISO 354 Sound insulation tested to AS/NZS ISO 717.1:2004 Tested in accordance with AS 1191-2002, with Rw determined to AS/NZS ISO 717.1 Fire resistance tested in accordance with AS 1530.4-2014, achieving FRL –/120/– All testing conducted by NATA-accredited laboratories Full test certificates available upon request |

| V225 | Sound absorption tested in accordance with ISO 354 Sound insulation tested to ISO 140-3 Fire safety: A1 Euroclass to EN 13501-1 All testing conducted by accredited laboratories Full test certificates available upon request |

| VR | Sound absorption tested in accordance with ISO 354 Sound insulation tested to ISO 140-3 Structural performance tested to UNI EN 14509 Thermal performance tested to UNI EN 14509 and EN ISO 6946 Fire safety compliant with relevant fire resistance standards All testing conducted by accredited laboratories Full test certificates available upon request |

How To Specify

SONIC SYSTEM ACOUSTIC MODULAR PANEL V50

| Category | Specification |

|---|---|

| System | Sonic System acoustic modular panel V50 |

| Construction | 50mm acoustic panel with solid steel faces, perforated internal face (38% open area) and high-density Rockwool core |

| Finish | Corrosion-resistant perforated steel |

| Acoustic Performance | Rw: 31 dB NRC: 1.00 |

SONIC SYSTEM ACOUSTIC MODULAR PANEL V100

| Category | Specification |

|---|---|

| System | Sonic System acoustic modular panel V100 |

| Construction | 100mm acoustic panel with solid steel faces, perforated internal face (38% open area) and high-density Rockwool core |

| Finish | Corrosion-resistant perforated steel |

| Acoustic Performance | Rw: 37 dB NRC: 1.10 |

SONIC SYSTEM ACOUSTIC MODULAR PANEL V100SP

| Category | Specification |

|---|---|

| System | Sonic System acoustic modular panel V100SP |

| Construction | Modular 100mm high-attenuation panel with thicker external steel, perforated internal face (38% open area) and high-density Rockwool core |

| Finish | Corrosion-resistant perforated steel |

| Acoustic Performance | Rw: 47 dB NRC: 1.00 |

SONIC SYSTEM ACOUSTIC MODULAR PANEL V225

| Category | Specification |

|---|---|

| System | Sonic System acoustic modular panel V225 |

| Construction | Lightweight 50mm acoustic panel with steel faces, perforated internal face (38% open area) and high-density Rockwool core |

| Finish | Corrosion-resistant perforated steel |

| Acoustic Performance | Rw: 24 dB NRC: 0.80 |

SONIC SYSTEM ACOUSTIC MODULAR PANEL VR (Acoustic Roof)

| Category | Specification |

|---|---|

| System | Sonic System acoustic modular panel VR – Acoustic Roof |

| Construction | Self-supporting structural roof panel (50–200mm) with Rockwool core |

| Finish | Structural steel exterior, optional perforated internal face |

| Acoustic Performance | Rw: 34 dB NRC: 1.00 |