Sonic System acoustic modular panel enclosure contains hydraulic pump noise

Capral Limited

Project Summary

Tailored enclosure for Capral supports compiance, health, and operational performance

Aluminium Manufacturing

Capral Limited

Penrith, NSW

About The Client

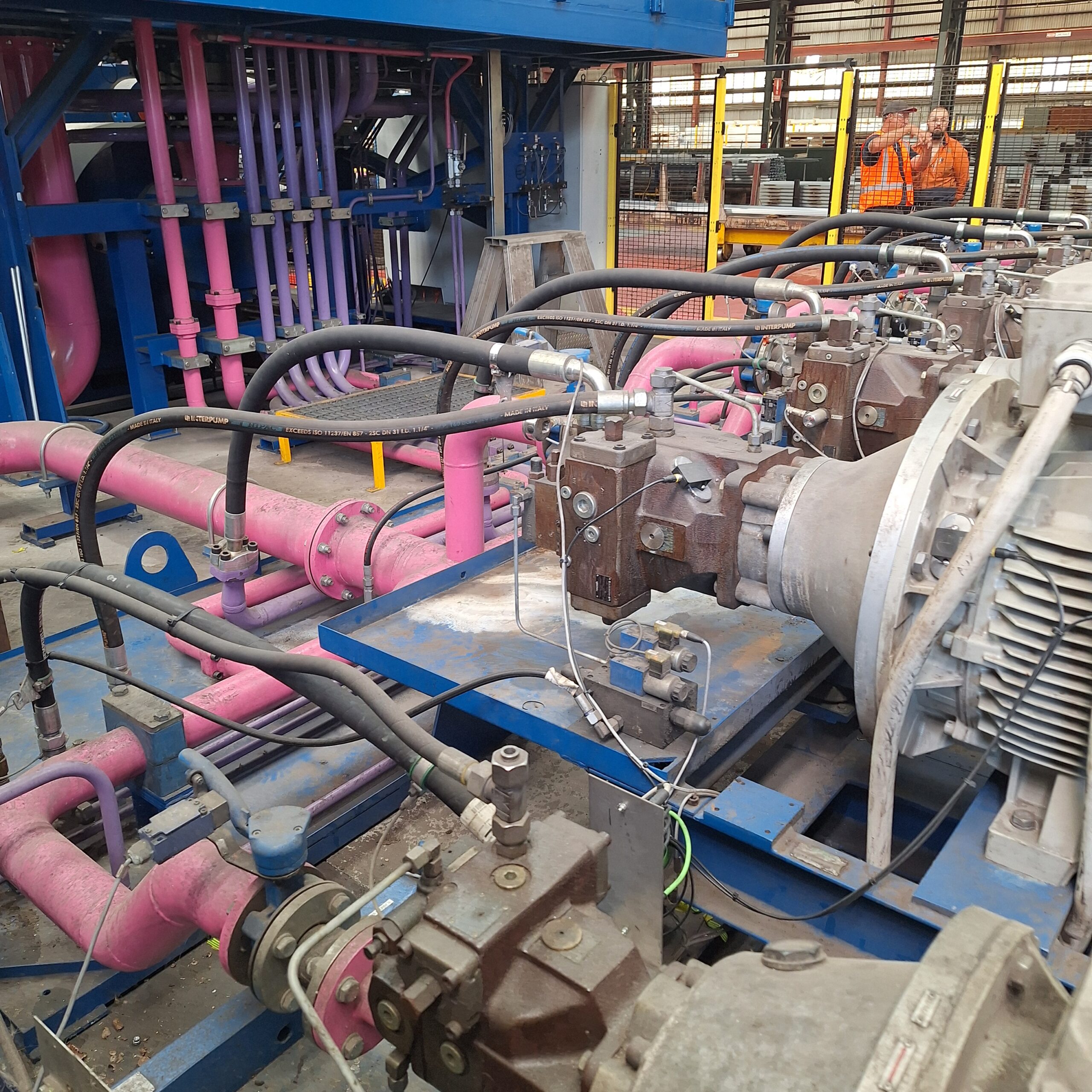

Capral Limited, one of Australia’s largest suppliers of aluminium products, faced a challenge at their Penrith facility. Hydraulic and vacuum pumps that operated in an open area were generating consistent, high-volume noise that impacted nearby workers and risked breaching environmental noise regulations.

The Challenge

Hydraulic and vacuum systems are known for their constant low-frequency sound output, which easily travels through industrial spaces and beyond property boundaries. At Capral’s site, this uncontained noise posed two key issues:

- Workplace health and safety concerns related to prolonged staff exposure

- Compliance pressure under EPA regulations governing noise emissions

Capral realised they needed more than just a sound barrier; they needed an engineered acoustic solution.

Our Approach

AcousTech designed a custom acoustic enclosure using the Sonic System acoustic modular panel solution. After a detailed site inspection and client brief, our engineering team developed CAD concepts to suit the new hydraulic pump infrastructure. The design incorporated airflow, personnel access, roof lift-off sections, and compliance with height clearance codes.

Installation of the enclosure was timed to coincide with a planned three-week plant shutdown for the setup of new machinery, ensuring minimal impact to operations.

The Delivered Solution

Capral’s new acoustic enclosure was constructed to the following specifications:

- Size: 7680mm (L) x 4900mm (W) x 3000mm (H)

- Panel system: Sonic System acoustic modular panel – V100 used throughout, with V50 panels on the end wall near pipe discharge to meet space restrictions

- Structure: Custom-designed and fabricated steel frame, supplied and installed by AcousTech

The Benefits for Capral Limited

- Supports EPA compliance

- Improves staff wellbeing

- Minimises equipment fatigue

- Allows seamless maintenance

- Reduces operational interruptions

Enhances plant appearance

Hydraulic and vacuum systems are known for their constant low-frequency sound output, which easily travels through industrial spaces and beyond property boundaries. At Capral’s site, this uncontained noise posed two key issues:

- Workplace health and safety concerns related to prolonged staff exposure

- Compliance pressure under EPA regulations governing noise emissions

Capral realised they needed more than just a sound barrier; they needed an engineered acoustic solution.