How to approach industrial noise control on complex projects

7 considerations when specifying acoustic solutions Industrial noise rarely resolves itself. That’s why, whether you’re working to reduce on-site exposure, contain emissions for compliance, or protect productivity, acoustic performance must be engineered into the solution, not simply bolted on as an afterthought. At AcousTech, we collaborate with consultants, engineers and project teams to design and…

7 considerations when specifying acoustic solutions

Industrial noise rarely resolves itself. That’s why, whether you’re working to reduce on-site exposure, contain emissions for compliance, or protect productivity, acoustic performance must be engineered into the solution, not simply bolted on as an afterthought.

At AcousTech, we collaborate with consultants, engineers and project teams to design and deliver acoustic systems that are technically accurate, operationally practical, and tailored to their environment.

Here are seven critical factors to address when planning industrial noise control for your project.

1) Identify where the noise is coming from

Understanding the noise source is the first step. It might be a high-pressure pump, an idling generator, or a grinding process that runs eight hours a day. Each source has a unique sound pressure level and acoustic footprint that demands a targeted response.

AcousTech insight

We begin every project with sound level assessments and noise mapping to determine whether isolation, shielding, or full containment will achieve the best result.

2) Measure the frequencies involved

Some materials block high-frequency noise well but fail to manage low-end rumble. Others provide broadband performance across a wide range of industrial noise types. The only way to select the right system is by analysing the problem sound’s frequency content.

AcousTech insight

Our team uses spectral data to inform material choice, ensuring the acoustic response addresses the actual problem – not just the perceived one.

3) Understand how sound travels through your site

Sound doesn’t always take the direct path. Reflections, flanking transmission and open-air movement can all compromise performance. Left unaddressed, these pathways can render a partial solution ineffective.

AcousTech insight

We use advanced predictive modelling and site data to plan sound containment systems that account for geometry, construction materials, access points and airflow.

4) Ensure your approach meets Australian Standards

In Australia, noise control is governed by specific standards. AS 1055 focuses on environmental noise impacts, while AS/NZS 1269 outlines safe exposure levels for workers. A compliant project needs more than guesswork, it needs data.

AcousTech insight

Our solutions are engineered to help our clients meet their obligations, without overspending or underperforming. We balance performance and practicality to ensure long-term confidence in compliance.

5) Manage the echo and reverberation within enclosed spaces

In workshops, plant rooms and sheds with reflective surfaces, noise lingers. This adds to overall exposure and reduces communication clarity. The longer sound persists, the higher the distraction and the greater the risk.

AcousTech insight

We incorporate sound-absorbing materials that reduce reverberation time and ensure the space remains workable, safe, and within acceptable acoustic limits.

6) Select the right materials for your site conditions

The best acoustic strategy will fall short if the materials used aren’t suited to the environment. Factors like exposure to dust, moisture, temperature shifts, and access requirements must shape the final design.

AcousTech insight

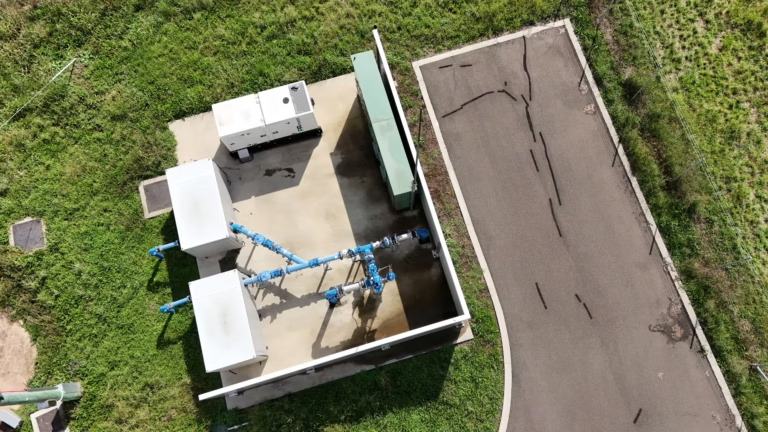

We offer purpose-built acoustic doors, enclosures, louvres and panel systems that can be integrated without compromising ventilation, safety or maintenance access.

7) Think long term, not just short term

Investing in a robust acoustic solution should deliver value well beyond the initial installation. Performance degradation, damage from forklifts, or difficulty servicing the system will cost more in the long run.

AcousTech insight

We prioritise durability and system resilience in every design. Our acoustic systems are built to perform year after year under real-world operating conditions, not just in a test lab.

Acoustic solutions with engineering integrity

Noise control should never be an afterthought. It affects productivity, compliance, and workforce wellbeing.

Yet with the right technical partner, it is possible to manage risk, enhance efficiency, and create a safer site, all without disrupting your operations.

To discuss your project and discover what’s possible when acoustic expertise meets industrial design, call AcousTech on 1300 508 232.

Trusted by engineers, built for performance. Powered by Flexshield.

That’s the Science of Silence.

Related Stories

-

Reshaping industrial noise control with sound science

How the AcousTech approach is revolutionising sound in Australia A quiet shift is happening across Australia’s industrial landscape. From high-output processing plants to remote infrastructure hubs, sound is no longer being treated as background clutter…. -

Smart industrial soundproofing solutions to transform your worksite

Noise control is not a nice-to-have – it’s a necessity Whether your industrial site is a mine, processing facility, or infrastructure project, its sound has a way of pushing its way into places it does… -

Why acoustics matter to us – and to your project

We don’t just install acoustic panels; we design silence with intent At AcousTech, sound isn’t an afterthought. It’s the thread running through every system we create, every project we contribute to, and every problem we…