Sonic Acoustic Mobiles

Maximum noise control for industrial settings

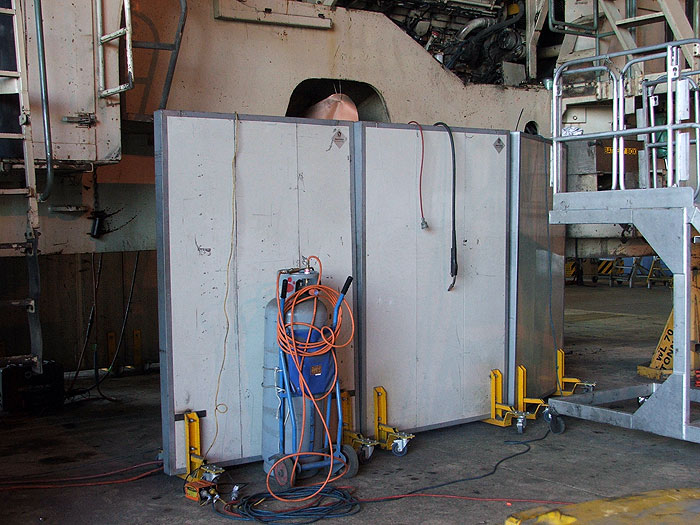

Transform your workspace with Sonic System acoustic mobile soundproofing panels

Key Applications

-

Temporary enclosure

-

Mobile barrier

-

Air arc gouging

Sonic System acoustic mobile soundproofing panels deliver excellent performance with the following specifications:

- Sound Absorption: NRC of up to 1.10, in accordance with ASTM C422-90, ensuring significant noise reduction.

- Noise Insulation: Rw37dB, in compliance with AS/NZS ISO717-1-2004, providing superior noise isolation.

- Fire Resistance: FRL of -/120/- in accordance with AS 1530-4-2014, ensuring a high standard of fire safety for materials.

Key Benefits

-

Customisable Sizes & Configurations

Available in various heights and widths with different materials and wheel carrier configurations, tailored to your facility’s specific needs.

-

High-Quality Construction

Featuring a sturdy outer face made of 0.8 mm thick metal, a high-density mineral wool core, and a reinforced perforated steel sheet for effective sound absorption.

-

Ultimate Mobility

Easy to move with high-quality castors, allowing flexibility to adjust to changing noise sources or workspace layouts.

-

Durability & Longevity

Non-woven glass wool facing protects the core and ensures the panels withstand the demands of the Australian environment.

-

Enhanced Acoustic Performance

Capable of absorbing sound across a wide range of frequencies to improve the acoustics of any space.

Photo & Video Gallery

-

Download the Sonic System Mobile Acoustic Panels Brochure for Flexible Noise Control

AcousTech’s Sonic System Acoustic Mobile Panels deliver superior noise reduction with unmatched mobility and versatility. Designed for industrial environments, these panels provide:

- Customisable sizes and configurations

- High-quality castors for easy repositioning

- NATA-accredited noise control performance

- Sound insulation up to Rw37dB

Ideal for metal stamping, grinding, air tools, and more, Sonic Mobile Panels adapt to your changing work environment, ensuring a safer, quieter workspace.

Download the brochure now to explore specifications and expert solutions!

-

Mobile Soundproofing Panels Construction

- Sturdy Outer Face: Made from 0.8 mm thick metal, offering durability and strength for extended use.

- High-Density Mineral Wool Core: Provides superior soundproofing by absorbing noise at different frequencies.

- Customisable Core Options: Add a sheet metal or visco-elastic core for improved performance when needed.

- Reinforced Perforated Steel Sheet: Features micro-strengthening ribs and various hole diameters, which offer sound absorption and prevent visual fatigue.

-

Testing and Compliance for Mobile Soundproofing Panels

- NATA-Accredited Test Results: Validated performance for Noise Transmission Loss and Noise Absorption.

- Sound Absorption: NRC of up to 1.10, tested in accordance with ASTM C422-90.

- Sound Insulation: Rw37dB, meeting the standard AS/NZS ISO717-1-2004.

- Fire Rating: Materials comply with the FRL rating of -/120/- according to AS 1530-4-2014.

- Durability: Materials are chemically neutral, corrosion-resistant and non-promoting of bacterial or mildew growth.

-

Mobile Soundproofing Panels Test Results

Sound absorption up to NRC of 1.10 in accordance with ASTM C422-90 Sound insulation up to Rw37dB in accordance with AS/NZS ISO717-1-2004 Reaction to fire (materials) FRL of -/120/- in accordance with AS 1530-4-2014 Sections 1, 2 & 3 -

How to Specify Mobile Soundproofing Panels

- Select Your Panel Dimensions: Choose the height and width that best suit your space.

- Choose the Core Configuration: Select the most appropriate core material (e.g. mineral wool, sheet metal or visco-elastic core).

- Pick the Mobility Option: Customise the castor configuration for ease of movement within your space.

- Ensure Compliance with Standards: Confirm that your specifications meet the required noise reduction and fire safety standards.